Meet Your Goals with CMD Upgrades and Parts Programs

Share

If you are completing your goals for 2023 – and many of us are – you may be considering how you will meet ambitious productivity targets, or ensure your group meets safety metrics. Maybe you are concerned about employees and labor. You’re thinking about how to train and onboard quickly, or how to make the systems you have error-resistant and easy to learn.

The upgrades program at CMD can help.

“A critical factor we consider when we develop equipment upgrades at CMD is how they can help our customers meet objectives,” says Craig Mickelson CMD Upgrades Sales Specialist. “We reach out to our customers to learn their needs and combine that information with our deep knowledge of converting equipment and processes to develop creative, cost-effective solutions that uniquely support our customers,” says Mickelson.

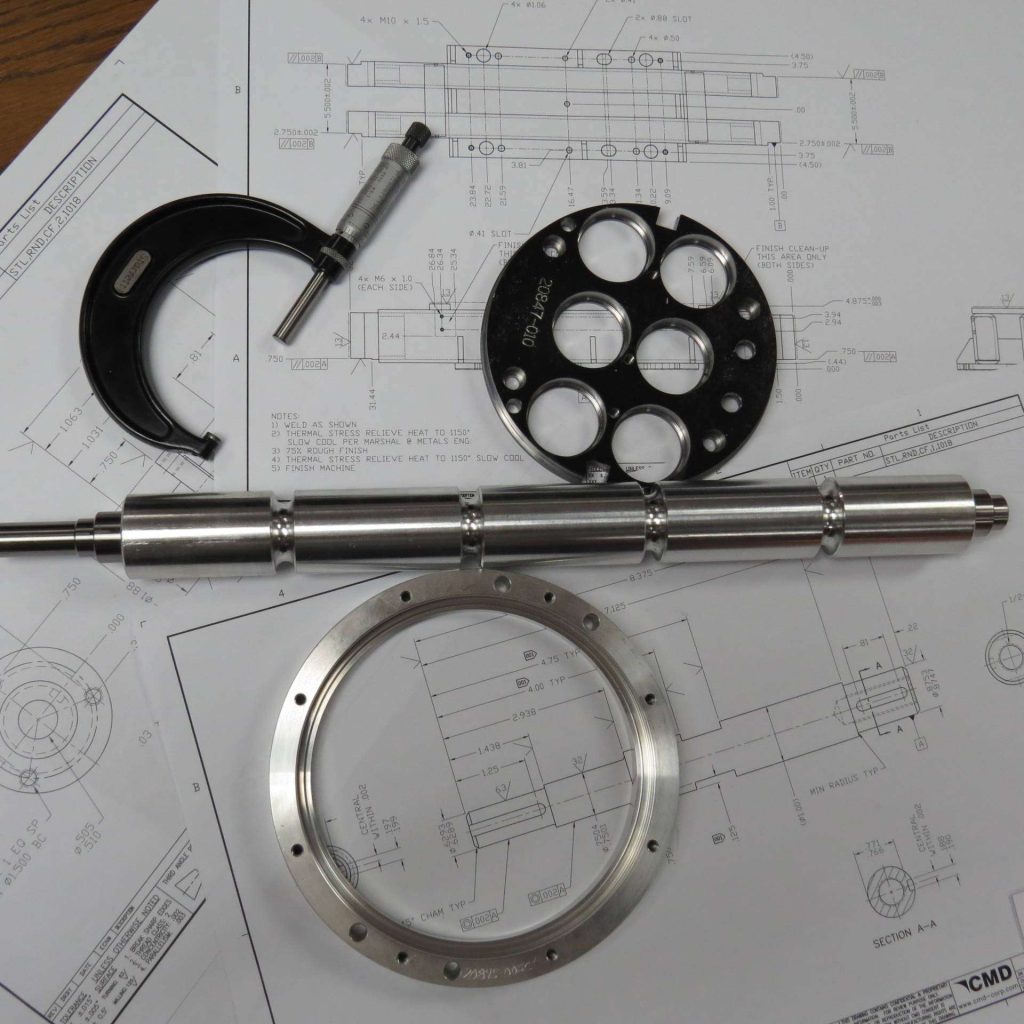

CMD equipment is known for its longevity – with systems still operational after 30+ years. Customers have access to a variety of upgrades for bag machines, winders, drawtape systems and pouch machines, and persistently develops new equipment and technology upgrades. A dedicated engineering team focuses on designing and manufacturing the upgrades that will bring the most value, in terms of higher productivity, ease of use enhancements or by bringing older machinery back to life with technology enhancements.

Featured Upgrade

For CMD extended-dwell bag machines including the 1270GDS

For CMD extended-dwell bag machines including the 1270GDS

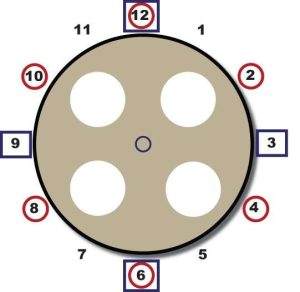

Enhance the flexibility of your rotary bag machine with the 4/6 Seal Bar Drum Upgrade! The addition of seal bars expands the process window, allows for more sealing dwell, and allows more flexibility in selecting seal bars for a broader range of products made on the same machine!

This upgrade also offers the high-efficiency sealing you need to convert today’s complex film blends used for compostable, recycled-content or degradable bags.

- Opens the process window with 59-86% more dwell time for increased efficiencies and enhanced product quality

- Allows for easy product transitions and set-up with touch screen selectable 6 or 4 seal bar operation

- Run with lower seal-bar temperatures, which improves the life of sealing components, including the sealing blanket

The additional seal bars included in this kit expand the bag machine’s capability to run in 6-bar mode or 3-bar mode for greater variety of bag sizes and film gauge requirements.

Secure 2022 Pricing! *

Contact Craig Mickelson, CMD Machine Upgrades Sales Specialist, for information today!

[email protected] 844-989-1025 or 920-380-8328

*available for a limited time

Comprehensive Spare Parts Department

In a recent satisfaction survey conducted by CMD, customers cited parts availability and parts service consistency and reliability as being of critical importance to their business.

We understand that quick delivery on needed parts is an important part of your uptime equation. CMD collaborates with customers to stock essential parts for fast and efficient fulfillment.

Experienced, in-house parts technicians and consultants are highly trained and experienced with your converting equipment. They are happy to assist in determining the correct parts to order to suit your immediateand long-term needs.

Timely, professional parts service and a regular program of developing value-rich technology equipment upgrades are part of the overall support program from CMD.

|  |  |

Additional Resources

>> Managing Component Obsolescene

>> Insights Data Management

>> Access to 24/7/365 Support

Leave a Reply

You must be logged in to post a comment.