Automation Proven Where It Matters Most

Automation is not new to CMD—it is a core capability built over decades of real production experience delivering integrated end-of-line automation solutions for demanding converting environments.

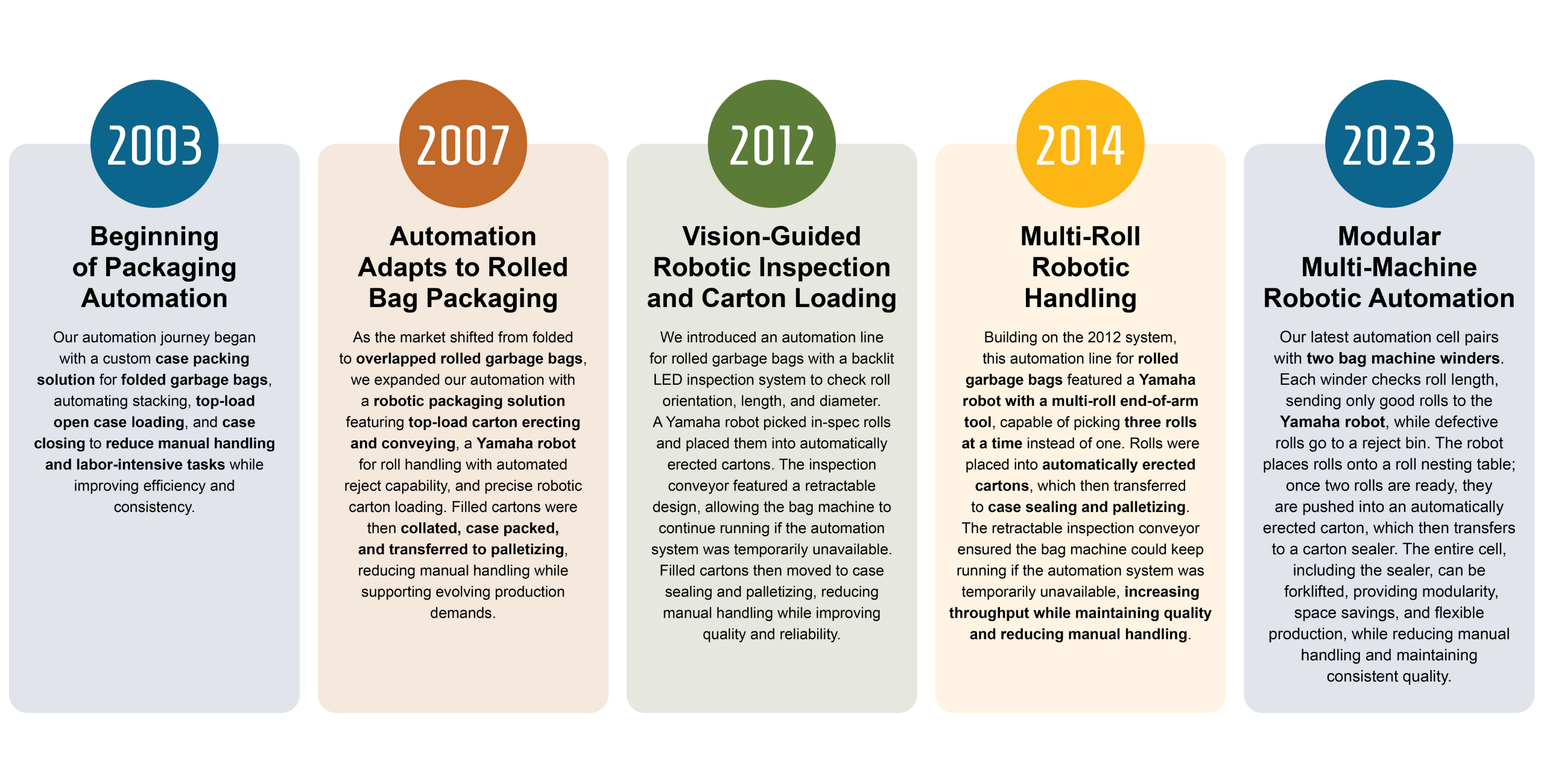

Over the past 25 years, CMD has fully or partially automated more than 100 converting lines in the trash bag market alone. This extensive installed base reflects deep application expertise, repeatable results, and automation systems engineered to perform under true 24/7 production conditions.

From automatic roll handling to preparing goods for shipping, CMD automation solutions are designed to meet the needs of your entire operation.

Automation That Strengthens Your Operation

CMD automation delivers measurable production and workforce advantages—built on deep converting expertise and long-term system support.

- Keep production lines running despite labor shortages

- Increased uptime, throughput, and output consistency

- Improved ergonomics and operator safety

- Seamless integration between converting, inspection, and packaging

- Future-ready platforms designed for expansion and upgrades

Today’s challenge isn’t just reducing manual work—it’s maintaining reliable production when qualified labor is increasingly difficult to find. CMD automation helps manufacturers protect output and continuity by designing systems that require fewer people, simplify operator roles, and run consistently shift after shift.

While CMD’s automation expertise is deeply rooted in trash bag converting, our capabilities extend across film converting and packaging applications. Every solution is backed by CMD’s in-house engineering, controls, integration, and long-term service support—ensuring performance well beyond installation.

If you are facing labor constraints, planning a capacity expansion, or modernizing an existing line, CMD is ready to help define the right automation strategy.

A Long-Term Production Partnership – Not Just An Automation Supplier

CMD delivers secondary packaging automation designed as a seamless extension of the converting line—and as a long-term investment in our customers’ operations.

Because CMD engineers build the upstream equipment, we understand the product, process, and performance requirements before packaging automation ever begins. That upstream ownership enables tighter mechanical integration, cleaner data handoffs, faster commissioning, and production systems that operate as one unified platform rather than disconnected machines.

What truly differentiates CMD is not only how we design automation, but how we support it. We remain engaged long after installation, partnering across the full equipment lifecycle with ongoing engineering support, optimization, upgrades, and expansion paths.

The result is secondary packaging automation built to evolve—delivering sustained uptime, scalable capability, and measurable lifetime value long after startup.

Help Your Operators Perform – Even as the Workforce Changes

Automation Built for Today’s Workforce

Today’s converting operations face a dual challenge: meeting aggressive production goals while navigating an increasingly tight labor market. Skilled operators are harder to find, training timelines are longer, and turnover continues to place a strain on both maintenance and production teams.

Modern production environments require systems that support faster onboarding, reduce dependency on highly specialized labor, and enable teams to perform at a high level—regardless of experience. Yet frequent workforce changes, language barriers, and varying skill sets make it increasingly difficult to maintain consistency across shifts and facilities.

That reality is why CMD has made intelligent automation a strategic priority.

Every converting line is different. Every operation has its own labor model, production demands, and growth objectives. Learning the nuances of complex equipment takes time—time many plants no longer have. CMD automation is engineered to reduce operational burden, standardize performance, and protect productivity in real-world manufacturing environments.

By embedding automation across material handling, process flow, and system integration, CMD helps manufacturers simplify operations, stabilize output, and keep lines running efficiently—even as the workforce evolves.

Let’s Work Together

If labor constraints, production inefficiencies, or growth plans are shaping your automation strategy, CMD is ready to help. Connect with our team to discuss your operation, your challenges, and the opportunities to strengthen performance through automation.

Contact Us