CMD Insights – Efficiency, Productivity and Financial Gain from IoT Technology

Share

Insights for Success

It’s not just the data, it’s what you do with it

Imagine driving your car and not knowing how fast you are going, or how much fuel you have left?

Your vehicle’s dashboard delivers important operating information to you every day. Depending on the sophistication of your vehicle, you may even receive predictive alerts. The message beneath your fuel gauge that tells you, “10 miles before empty” is an example of an actionable deliverable served up based on data reported from your vehicle’s system.

Similarly, industrial systems like your CMD Machinery can generate a wealth of data that can be collected with report-outs in real time. But the data is the most powerful when it provides you with actionable information that:

• Improves performance

• Predicts and prevents downtime

• Measures output and productivity

CMD is now offering a unique, IoT support tool that drives productivity, efficiency and profitability for converters. “CMD Insights is a customizable data management tool that delivers real-time actionable data,” says Craig Mickelson, CMD Machine Upgrade Specialist and CMD Insights specialist. “Our customizable dashboards deliver powerful insights that save our customers time, money and resources.”

One example is the saving of human effort.

Free Up Personnel Hours

In the car example above, you might receive a notification that you are due for an oil change in 50 miles. That is a simple, routine maintenance alert. But if you are not notified and are not one to keep good records and diligently visit the auto shop to have your car maintained, it could result in a disastrous breakdown, stranding you on the highway and costing you a lot of money and inconvenience as your car is repaired from a major system meltdown. All that repair work costs human effort, effort that could be used elsewhere had there been a predictive alert.

“You may want to be alerted as to next predicted service dates. By communicating information that can forestall a breakdown, human effort is saved, and machine uptime is ensured,” says Mickelson.

Uptime, Uptime, Uptime

“Our focus at CMD is to go the extra mile, to provide customized services to deliver the best uptime efficiency in the industry,” says Mickelson. “We understand the importance of real-time throughput and uptime metrics.”

For machinery, having the data to communicate production, availability and uptime reliability can mean the difference between attracting and retaining customers and losing them. For future-proofing uptime reliability, isolating and understanding the most common or frequent faults allows the management of the conditions causing the faults, resulting in less downtime and fewer near misses.

Customize Your Key Performance Indicators

Collecting real time data is one thing; serving up actionable deliverables is another. Every business has specific KPIs that are critical for their goals and machines success. That’s where customization comes in.

“CMD Insights can be customized to report out the key performance indicators (KPIs) defined by the each individual business,” says Mickelson, “We’ll develop the dashboard that gives you the information you need in real time directly from the machine’s controller, from any web-based device.”

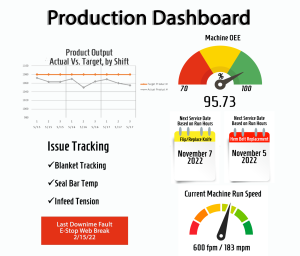

This a sample dashboard that illustrates how clean and simple it can be to get the information you need for remote management of your business.

The Key Performance Indicators selected are:

• Machine OEE (Overall Equipment Effectiveness)

• Total Product Output

• Current Machine Run Speed

• Required service dates predicted based on run hours

• Issue tracker

• Date of last downtime fault

“The beauty of this ioT tool is the ability to customize the inputs/outputs to suit the goals of the converter,” says Mickelson. “CMD is invested in continuing to develop the technology to provide even more actionable deliverables through digital transformation tools like CMD Insights.”

To find out what makes CMD Insights different,

please reach out to:

Craig Mickelson

Machine Upgrade Specialist

[email protected]

Leave a Reply

You must be logged in to post a comment.