Detect, analyze, and resolve defects with pinpoint accuracy, helping you boost quality, reduce waste, and keep production running at peak performance.

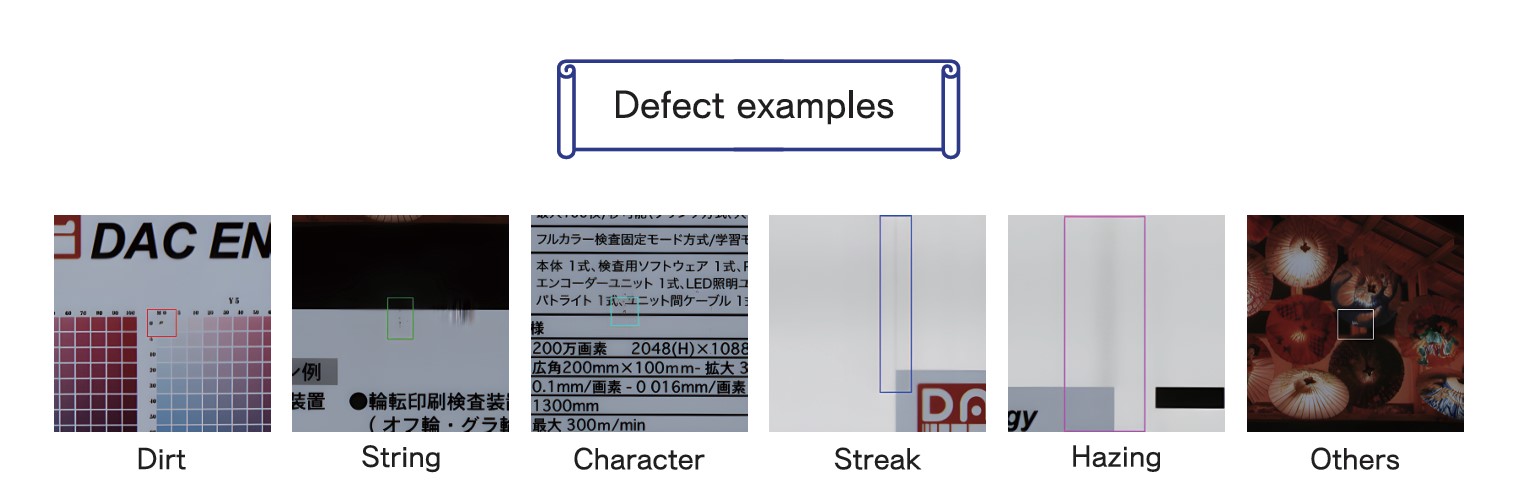

- Real-time defect detection & analysis

- Enhanced precision to boost efficiency & cut waste

- Expert guidance on how smart inspection leads to flawless packaging

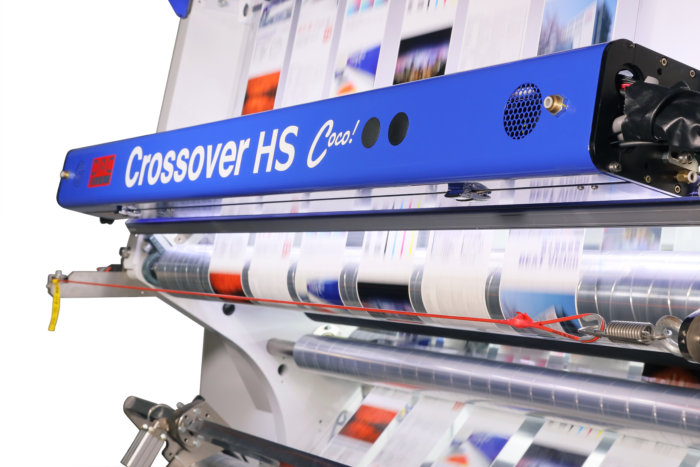

CMD and DAC combine to make web-inspection simple, featuring:

- Proprietary optics, proprietary lighting design, and proprietary defect detection and classification circuitry

- High-speed 100% inspection that is easy to use and impervious to software viruses creates a robust and repeatable process

- Simple, two-touch basic operation set-up

- Full-color image reproduction

- Programmable alarm thresholds

- Broad range of options to enhance the user experience

- Flexibility and simplified operation at a budget-friendly price

- Local service, support, and spare parts